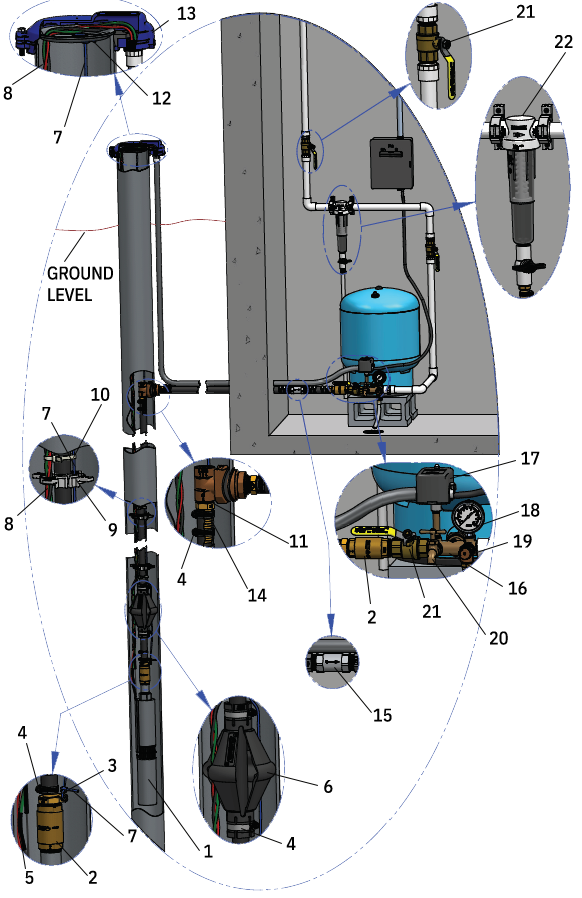

How To Install A Submersible Well Pump Diagram

Ever look at some parts and wonder "Where does this belong?" or "How do these parts work together?" In a submersible pump installation, there are a scattering of unlike products that work together, playing an important role in the overall function of the submersible pump. Some products may have roles more centre phase, simply accept one role away and you and your pump could be in danger.

In this mail, we take a expect at a variety of products for submersible pumps, what their roles are and how they work together. Let'south take a expect.

Submersible Pump Components

- Submersible Pump

- Check Valve

- Easy Necktie Adapters

- Clamps

- Heat Shrink Splice Kits

- Torque Arrestor

- Safety Rope

- Pump cablevision

- Cablevision Guards

- Cable Ties

- Pitless Adapters

- Rope Hangers

- Well Caps

- Insert Adapters

- Flow Command Valves

- Tank Tees

- Pressure Switch

- Pressure Gauges

- Relief Valves

- Bleed Valves

- Ball Valves

- Sediment Filter

ane. Submersible Pump

A submersible pump allows for moving water from the ground upwards. They are designed to push the water up to the surface in a very efficient style.

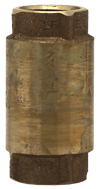

2. Check Valve

The placement and number of bank check valves required for a system is based on the depth of the pump setting in the well. Installation of 200 feet or less require one check valve on the pump discharge and ane on the surface of the well. Settings 200 feet or deeper may require multiple bank check valves. Some thing to consider during installation is the weight of piping, water and submersible pump, head loss of the valves, friction loss of the piping, velocity of water and water hammer. For more on check valves and what their job is, cheque out taking a look at check and foot valves.

The placement and number of bank check valves required for a system is based on the depth of the pump setting in the well. Installation of 200 feet or less require one check valve on the pump discharge and ane on the surface of the well. Settings 200 feet or deeper may require multiple bank check valves. Some thing to consider during installation is the weight of piping, water and submersible pump, head loss of the valves, friction loss of the piping, velocity of water and water hammer. For more on check valves and what their job is, cheque out taking a look at check and foot valves.

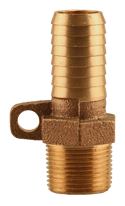

3. Like shooting fish in a barrel Tie Adapters

Like shooting fish in a barrel necktie adapters thread into the belch on the check valve at the submersible pump and inserts  into poly riser pipe. A 2d adapter can be threaded into the pitless adapter at the well caput and then connects to the poly riser pipe. The lug with a hole, or the rope eye, provides a simple means to securely fasten the safe rope or cable or to secure the submersible pump to the well head in instance of a pipe failure. Available in bronze and stainless.

into poly riser pipe. A 2d adapter can be threaded into the pitless adapter at the well caput and then connects to the poly riser pipe. The lug with a hole, or the rope eye, provides a simple means to securely fasten the safe rope or cable or to secure the submersible pump to the well head in instance of a pipe failure. Available in bronze and stainless.

iv. Clamps

Hose clamps are designed for sealing poly pipe to spinous insert fittings, making a positive watertight seal and pull-off proof connection. Using an all 300 course stainless steel clench ensures the clamp will last the life of the system for water well installations or where maximum corrosion resistance is required. For a more in depth look at clamps, check out The pro'due south guide to gear clamps webinar.

Hose clamps are designed for sealing poly pipe to spinous insert fittings, making a positive watertight seal and pull-off proof connection. Using an all 300 course stainless steel clench ensures the clamp will last the life of the system for water well installations or where maximum corrosion resistance is required. For a more in depth look at clamps, check out The pro'due south guide to gear clamps webinar.

v. Heat Compress Splice Kits

Heat compress splice kits are designed for under water electrical connections between the pump cable  and the leads on the pump motor. The connexion is made by cutting the cables in a staggered position to decrease the outer cable diameter. This is an important step in gild to reduce the risk of damaging the splice due to abrasion when the pump is lowered into the well. To look at splice kits a little closer, bank check out our blog, What the Heck are Oestrus Shrink Kits?

and the leads on the pump motor. The connexion is made by cutting the cables in a staggered position to decrease the outer cable diameter. This is an important step in gild to reduce the risk of damaging the splice due to abrasion when the pump is lowered into the well. To look at splice kits a little closer, bank check out our blog, What the Heck are Oestrus Shrink Kits?

half-dozen. Torque Arrestor

Torque arrestors are specifically designed to keep the submersible pump centred and to prevent any twisting in the well casing. Torque arrestors as well protect the pump cablevision and are typically installed straight above the pump on the riser piping. They can be installed on 1" and 1- 1/iv" riser pipe. For more on torque arrestors, cheque out our blog, Why Install a Torque Arrestor?

Torque arrestors are specifically designed to keep the submersible pump centred and to prevent any twisting in the well casing. Torque arrestors as well protect the pump cablevision and are typically installed straight above the pump on the riser piping. They can be installed on 1" and 1- 1/iv" riser pipe. For more on torque arrestors, cheque out our blog, Why Install a Torque Arrestor?

vii. Safety Rope

Safety rope tin can be found connected directly to the submersible pump and secured at  the well head. The principal role is to prevent the pipes from separating which could result in the pump beingness lost at the bottom of the well. Safety rope can also provide a backup to enable the installer to pull the pump from the well if the riser pipe fails. Every pump should take a safety rope secured to information technology before hanging information technology in the well. To look at the different types of safe rope available, check out our weblog, All Almost the Unlike Types of Rubber Rope.

the well head. The principal role is to prevent the pipes from separating which could result in the pump beingness lost at the bottom of the well. Safety rope can also provide a backup to enable the installer to pull the pump from the well if the riser pipe fails. Every pump should take a safety rope secured to information technology before hanging information technology in the well. To look at the different types of safe rope available, check out our weblog, All Almost the Unlike Types of Rubber Rope.

8. Pump Cable

Submersible pump cable is used to supply the ability to the submersible pumps. Typical pumps used in a submersible pump installation are either a 2 or iii wire pump. The two wire pumps take the starting capacitor congenital into the submersible motor whereas the 3 wire pumps exercise not have the capacitor built into the motor, they crave a command box which is normally found in the pump house at the well head. For more than on pump cable, cheque out our mail service How to Get Pumped Almost Pump Cablevision.

Submersible pump cable is used to supply the ability to the submersible pumps. Typical pumps used in a submersible pump installation are either a 2 or iii wire pump. The two wire pumps take the starting capacitor congenital into the submersible motor whereas the 3 wire pumps exercise not have the capacitor built into the motor, they crave a command box which is normally found in the pump house at the well head. For more than on pump cable, cheque out our mail service How to Get Pumped Almost Pump Cablevision.

9. Cable Guards

Cable guards go on the riser pipage centred in the well to prevent damage to the pump wire. If the pump cablevision is not properly protected, the insulation on the wires feeding the pump can go worn out due to rubbing against the inside of the well casing. Every time the pump stops or starts, the whole installation moves in response. Afterwards years of this activity, the wire insulation will thin resulting in a curt circuit.

cablevision is not properly protected, the insulation on the wires feeding the pump can go worn out due to rubbing against the inside of the well casing. Every time the pump stops or starts, the whole installation moves in response. Afterwards years of this activity, the wire insulation will thin resulting in a curt circuit.

x. Cable Ties

Cablevision ties are used to effectively secure the riser pipe to the pump cable between the cable guards. Some codes require the cable ties to be attached to the riser pipe at intervals of no greater than ten feet apart. Check out our web log, Types of Cable Ties to await at them a little closer!

Cablevision ties are used to effectively secure the riser pipe to the pump cable between the cable guards. Some codes require the cable ties to be attached to the riser pipe at intervals of no greater than ten feet apart. Check out our web log, Types of Cable Ties to await at them a little closer!

xi. Pitless Adapters

Slide type pitless adapters allow for an piece of cake connectedness of the riser pipe from the submersible pump to the hush-hush discharge pipe. The discharge pipe transfers the h2o to your home below frost level. The threaded tapping on the pitless elbow allows the adapter to be connected to the lift out pipe to lift riser piping and the pump assembly up out of the well. To look at slide pitless adapters a little closer, check out Slide vs Spool Pitless Adapters: What'due south the Difference?

the hush-hush discharge pipe. The discharge pipe transfers the h2o to your home below frost level. The threaded tapping on the pitless elbow allows the adapter to be connected to the lift out pipe to lift riser piping and the pump assembly up out of the well. To look at slide pitless adapters a little closer, check out Slide vs Spool Pitless Adapters: What'due south the Difference?

12. Rope Hangers

Did you lot know rope hangers were invented past Mel Boshart and are only available at Boshart Industries? Rope hangers were designed to provide an easier method  of attaching the prophylactic rope securely to the well casing at the well caput, rather than fastening the rope straight to the other internal components. The rope hanger can easily exist removed and ready to the side when the pump is pulled from the well if the well needs to be replaced or serviced. For more on safety rope and rope hangers, check out all the different types of safety rope.

of attaching the prophylactic rope securely to the well casing at the well caput, rather than fastening the rope straight to the other internal components. The rope hanger can easily exist removed and ready to the side when the pump is pulled from the well if the well needs to be replaced or serviced. For more on safety rope and rope hangers, check out all the different types of safety rope.

13. Well Caps

Well caps are designed to comprehend the top of the well casing. They prevent debris from entering the well.  At that place are a variety of types of well caps but they all provide a watertight seal to protect the well from whatsoever contamination. To learn more about the different types of well caps and the different materials they come in, cheque out this blog post.

At that place are a variety of types of well caps but they all provide a watertight seal to protect the well from whatsoever contamination. To learn more about the different types of well caps and the different materials they come in, cheque out this blog post.

xiv. Insert Adapters

An insert adapter has one end that is insert and the other end is MPT (Male person Piping Thread). When hanging a pump on the poly riser pipe, it is recommended to use an actress long insert adapter for added protection of the pump from accidentally pulling out of the insert. Yous can also double or triple clench the insert fittings to ensure the connection volition never slip. For a closer look at bronze insert fittings, check out our blog, four Features to Wait for in Statuary Insert Fittings.

An insert adapter has one end that is insert and the other end is MPT (Male person Piping Thread). When hanging a pump on the poly riser pipe, it is recommended to use an actress long insert adapter for added protection of the pump from accidentally pulling out of the insert. Yous can also double or triple clench the insert fittings to ensure the connection volition never slip. For a closer look at bronze insert fittings, check out our blog, four Features to Wait for in Statuary Insert Fittings.

fifteen. Flow Control Valves

In whatsoever well installation, a flow control provides protection to the submersible pump in  low producing wells. Flow controls allow the aquifer to sustain a static water level in the well and not allow it to fall below the submersible pump to prevent the pump from running dry out due to over pumping the well. Y'all tin can install a flow command anywhere between the submersible pump and the tank tee at the pressure level tank connection, merely they tin can be used in other locations besides. To swoop into flow controls a little deeper, cheque out our blog, What the Heck is a Period Control?

low producing wells. Flow controls allow the aquifer to sustain a static water level in the well and not allow it to fall below the submersible pump to prevent the pump from running dry out due to over pumping the well. Y'all tin can install a flow command anywhere between the submersible pump and the tank tee at the pressure level tank connection, merely they tin can be used in other locations besides. To swoop into flow controls a little deeper, cheque out our blog, What the Heck is a Period Control?

16. Tank Tees

.png?width=150&name=07ST-13SF-2U%20(top).png) Tank tees are multi-port fittings designed specifically to connect a tank to the h2o system. Having the multi-port feature allows 1 fitting to do the job as eight or more than pipe fittings. The connection on the legs goes to the tank and one of the lateral connections goes to the pump. Some other connection goes to the plumbing system. H2o from the pump can then go either into the tank or direct into the plumbing. To accept a closer await at tank tees, check out our weblog, Why Not All Tank Tees are Created Equal.

Tank tees are multi-port fittings designed specifically to connect a tank to the h2o system. Having the multi-port feature allows 1 fitting to do the job as eight or more than pipe fittings. The connection on the legs goes to the tank and one of the lateral connections goes to the pump. Some other connection goes to the plumbing system. H2o from the pump can then go either into the tank or direct into the plumbing. To accept a closer await at tank tees, check out our weblog, Why Not All Tank Tees are Created Equal.

17. Pressure Switch

Pressures switches control the submersible pump operations due to it's built in diaphragm that moves back and along reacting to the water organization pressure. Force per unit area switches come up in standard, medium and heavy-duty models that handle a wide variety of electric and pressure ratings. For more data on pressure switches, check out our web log, How to Properly Adjust your Pressure level Switch.

back and along reacting to the water organization pressure. Force per unit area switches come up in standard, medium and heavy-duty models that handle a wide variety of electric and pressure ratings. For more data on pressure switches, check out our web log, How to Properly Adjust your Pressure level Switch.

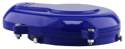

18. Pressure level Gauges

A pressure guess allows y'all to hands monitor what the force per unit area system is doing and to confirm what the cutting-in and cut-out pressure level settings of the switch are. They are installed in one of the two up facing accompaniment ports on the tank tee head. Glycerine filled gauges can reduce whatever movement that could occur on the indicator pointer due to system vibrations. Bank check out our web log, When to Select a Liquid VS Dry Pressure Gauge for more information.

A pressure guess allows y'all to hands monitor what the force per unit area system is doing and to confirm what the cutting-in and cut-out pressure level settings of the switch are. They are installed in one of the two up facing accompaniment ports on the tank tee head. Glycerine filled gauges can reduce whatever movement that could occur on the indicator pointer due to system vibrations. Bank check out our web log, When to Select a Liquid VS Dry Pressure Gauge for more information.

19. Relief Valves

A relief valve provides protection to the plumbing organization from excessive pressure if a force per unit area switch were to neglect allowing the system to continue building pressure beyond the pre-fix pressure of the switch. Excessive pressure could outcome in major failure of the plumbing piping and the plumbing components, potentially resulting in h2o harm. Take a closer wait at relief valves here.

were to neglect allowing the system to continue building pressure beyond the pre-fix pressure of the switch. Excessive pressure could outcome in major failure of the plumbing piping and the plumbing components, potentially resulting in h2o harm. Take a closer wait at relief valves here.

xx. Bleed Valves

.png?width=150&name=0852-07NL%20(cert).png) A drain valve is installed in the 2nd outward facing accompaniment port. Drain valves provide a means to take water samples, larn water from systems and allows access to bleed the tank and water system if the pressure tank needs to be replaced. Drain valves are also known as sediment faucets or banality drain valves.

A drain valve is installed in the 2nd outward facing accompaniment port. Drain valves provide a means to take water samples, larn water from systems and allows access to bleed the tank and water system if the pressure tank needs to be replaced. Drain valves are also known as sediment faucets or banality drain valves.

21. Ball Valves

A ball valve should be installed on the discharge side of the force per unit area tank, providing a ways of  isolation of the plumbing system from the h2o well pressure system. Ball valves provide a mode to close off the water supply to the firm in the event of a component failure in the plumbing system. For more information on ball valves, cheque out our blog, What the Heck is a Ball Valve?

isolation of the plumbing system from the h2o well pressure system. Ball valves provide a mode to close off the water supply to the firm in the event of a component failure in the plumbing system. For more information on ball valves, cheque out our blog, What the Heck is a Ball Valve?

22. Sediment Filter

A sediment filters job is to remove the sediment from your h2o. This protects from sediment entering any h2o handling equipment like softeners or hot water heaters. Having no sediment in the water treatment equipment increase the efficiency and longevity of the equipment. To get more than details regarding spin out filters and separators, check out our post, Understanding Sediment Filters & Separators.

A sediment filters job is to remove the sediment from your h2o. This protects from sediment entering any h2o handling equipment like softeners or hot water heaters. Having no sediment in the water treatment equipment increase the efficiency and longevity of the equipment. To get more than details regarding spin out filters and separators, check out our post, Understanding Sediment Filters & Separators.

As y'all can see, each production is crucial to ensure a prophylactic and successful submersible pump installation. When you install a submersible pump, employ this list to confirm you have not forgotten any cardinal parts, ensuring the safety of you lot and the pump.

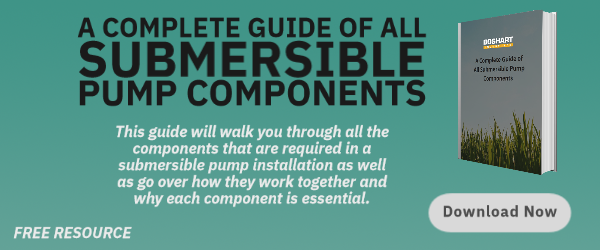

Desire to look at all of the components of a submersible pump installation closer? Cheque out, A Complete Guide of All Submersible Pump Components Ebook.

Source: https://blog.boshart.com/components-of-a-typical-submersible-pump-installation

Posted by: nancewhince00.blogspot.com

0 Response to "How To Install A Submersible Well Pump Diagram"

Post a Comment